Industrial EO Reclamation

BOAZ Cryogenic recovery & Abatement system.

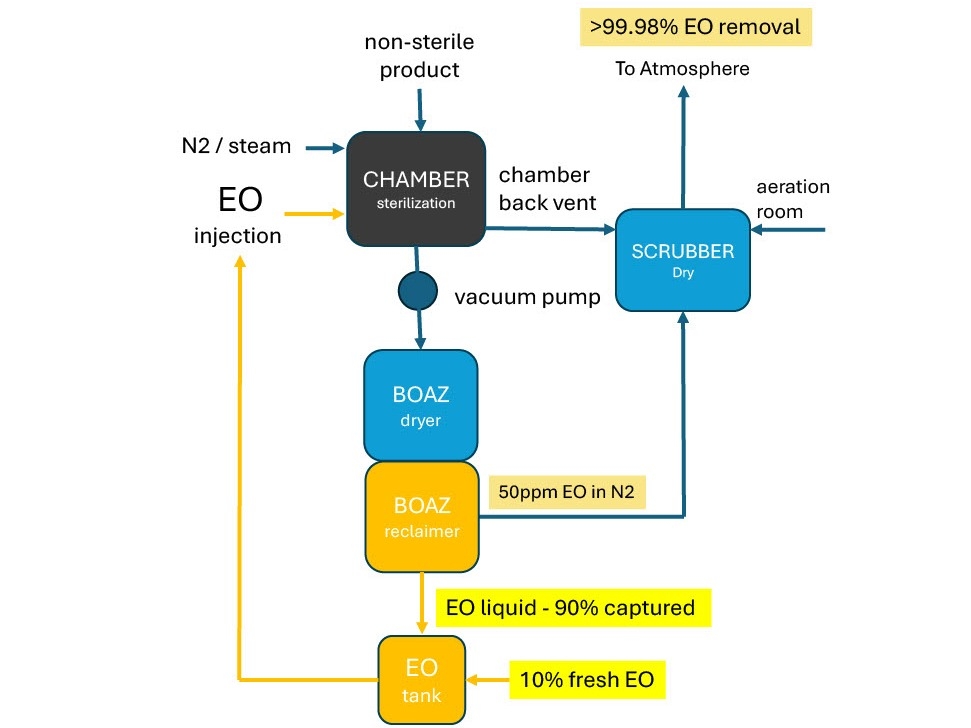

Advanced Sterilization Techniques (AST) is based in Taiwan and has invented, patented, and built a system to convert gaseous EO derived from a sterilizer, back into 100% liquid EO. With a BOAZ system in Taiwan, it has been successfully operating on four 4 pallet sterilizers for over 2 years now.

Meanwhile, a new BOAZ system is being installed in a brand new EO sterilization facility in Taiwan and plans to be fully operational in 2025. This BOAZ system can recover 90% of the gaseous EO amongst three sterilizers - one with a 7-pallet sterilizer, and the other two with 12 pallet sterilizers.

The BOAZ results in significant financial savings in capital equipment cost, daily operating cost and in total EO cost.

With the new EPA and FDA requirements scheduled to go into effect in April 2026, the timing for the launch of this new BOAZ technology and its soon-to-be worldwide availability is exactly right for those that utilize pure EO for medical device sterilization.

The BOAZ System’s Notable Benefits Are:

- Significantly reduces capital equipment cost for EO emission control.

- Significantly reduces cost of EO used to sterilize as 90% of the EO gas from the sterilization process is recovered.

- Significantly reduces the day-to-day EO emission utility operating cost for EO emission control.

- Installation of a BOAZ changes the control requirement for meeting the new EPA rule, as the facility Annual EO Usage is reduced to only 1/10th of previous level.

Additionally, AST has chosen to integrate Picarro’s advanced EO monitoring solutions, providing the sterilization industry with a clear pathway to compliance and process optimization.

Picarro’s CRDS-based monitoring systems have been widely deployed at leading medical device companies and contract sterilization facilities.

“With the growing pressure to meet increasingly stringent EO control, abatement, and monitoring requirements under EPA NESHAP and FIFRA, the industry needs trusted data more than ever,” said Dave Miller, Vice President of Picarro’s Environmental Solutions Business. “By leveraging Picarro’s leadership in industrial VOC monitoring applications, AST is driving much needed innovation for process optimization and compliance, giving EO sterilization providers a powerful and reliable solution to tackle emerging regulatory challenges.”

With this in mind, we are excited to announce that this proven technology will soon be available for all pure EO sterilizers worldwide, as well as opening a new corporate sales office in the US.

Click the Link Below for Further Information on Boaz EtO Reclamation System –TAST Experience: